WhatsApp)

WhatsApp)

The posting of Martin Luther''s ninetyfive theses in 1517 set off the spark that ignited the Protestant Reformation, and the Reformation in turn marked a ...

5 If the gold is still not pure enough, it can be smelted. Smelting involves heating the gold with a chemical substance called flux.

Delivery of Fill Dirt, Topsoil, Limestone, Sand and, Lowest Prices For Bulk Material in Lafayette and Surrounding Now Same Day

Slag is the glasslike byproduct left over after a desired metal has been separated (, smelted) from its raw ore. Slag is usually a mixture of metal oxides and ...

The Foundry DIY (Do It Yourself) Zone, How to Metal Casting and Scrap Metal Recycling with Foundry Furnace / Melting Furnance, Information and foundry supplies

FAQ (Frequently Asked Questions) This list of questions are some which are frequently asked in email and on the forum. Hopefully this list will save time for ...

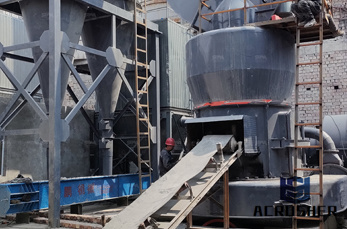

Smelting is a form of extractive metallurgy; its main use is to produce a base metal from its ore. This includes production of silver, iron, copper and other base ...

Although Norse people knew of mining and mined some iron ore in a variety of locations throughout Scandinavia, most Viking era iron was smelted from bog iron.

process of traditional iron smelting in eastern zambia and its possible impac on appropriate technology

Copper is one of the basic chemical elements. In its nearly pure state, copper is a reddishorange metal known for its high thermal and electrical conductivity.

A look at the discovery of the iron plate allegedly found inside the Great Pyramid at Giza

Metal extraction process in which an ore (usually mixed with purifying and/or heat generating substances such as limestone and coke) is heated at high temperature in ...

MTig Welding Tungsten inert gas (TIG) welding anufacturers, welding consultants for air plasma cutting and welding machines systems, welding rectifiers, plasma ...

Structural engineer Michael Bussell explains the highly significant but often overlooked role of structural ironwork in 19th century British architecture, exploring ...

A Brief History of Iron and Steel Production. by. Professor Joseph S. Spoerl. Saint Anselm College The production of iron by humans began probably ...

Secrets of the Viking Sword. A modernday swordsmith reverse engineers the ultimate weapon of the Middle Ages—a sword both prized and feared. Airing March 29 ...

Why using ArnoBrik Series Briquetting Presses? In contrast to loose swarf, briquettes offer huge cost savings. Because briquettes emit virtually no fluids, simpler ...

Timeline of metal processes, heat treatments and surface technology from 8700 BC to Modern Day

Since its formation, Atoll Metal Recovery has built 11 major metalfromslag recovery plants in Southern Africa, capable of processing between 120 and 200 t/h of slag.

Start melting and pouring metal easily at almost no cost and while having fun! This booklet explains how to build the furnace and how to use it to melt and pour metal!

How Steel is Made: a Brief Summary of a Blast Furnace: There are two types of metals, ferrous nonferrous. Ferrous comes from, or contains iron, while NonFerrous ...

WhatsApp)

WhatsApp)