WhatsApp)

WhatsApp)

While experimenting with different ways to make Iron Oxide to use in ... powder. The difficulty with this process is ... /id/ProduceaRich ...

Their magnetic strength is enhanced by aligning the powder ... used to produce powerful neodymiumiron ... process of making a permanent magnet is ...

Both of these processes are used to produce powder metal parts made of aluminum, copper, and iron. Sintered metal parts include sintered steel and sintered bronze parts, and they are made by melting metal powder and forming it into a shape.

Powder metallurgy (PM) is a term covering a wide range of ways in which materials or components are made from metal powders. PM processes can avoid, or greatly reduce, the need to use metal removal processes, thereby drastically reducing yield losses in manufacture and often resulting in lower costs.

Production of sponge iron powder by reduction of rolling mill scale ... produced and the process used. The iron ... reduction of rolling mill scale to sponge ...

A process for preparing iron powder suitable for use in preparing the ironpotassium perchlorate heatpowder fuel mixture used in thermal batteries, comprises preparing a homogeneous, dense iron oxide hydroxide precipitate by homogeneous precipitation from an aqueous mixture of a ferric salt, formic or sulfuric acid, ammonium hydroxide and .

Iron powder is an aggregate of iron particles with sizes of approximately 20200 μ m. It is treated as a powder using the particle size distribution, apparent ...

Sintering is part of the firing process used in ... of iron. Sintering is static when a metal powder ... on sintering dissimilar materials to produce ...

Mar 07, 2015· ... forming during the drying process I decided to use this variation for ... iron powder is moisturised to ... /id/Makeagood,cheap ...

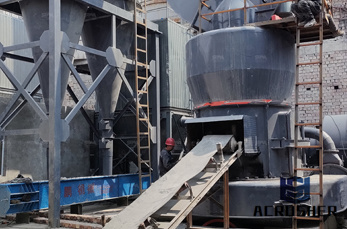

which process is used to produce iron powder. Iron ore crusher,iron ore grinder,iron ore crushing Iron ore crushing process is the necessary step in order to produce ...

Ironbased powder composition for use in powder metallurgy, process for its production and process for producing ironbase sintered material US A

Jul 02, 2017· Iron powder is iron that''s been put through a centrifuge or an atomization process. The main uses of iron powder are in making...

Iron Ore Processing for the Blast Furnace ... Creating steel from lowgrade iron ore requires a long process of mining, ... powder and mixed with water.

Produce absorbing coating by using carbonyl iron powder Absorbing material can be used in airplane coating for reducing its reflector to radar and reducing radar cross

In the powder metallurgy process, the industrial pieces are produced through compacting powder in the frame and sintering. within a controlled setting. As a natural character of powder metallurgy process a disadvantage is the production of a work piece. with poor mechanical properties due to its porosity.

Common materials used to manufacture cement ... rocklike substance that is ground into the fine powder that we commonly ... United States use a wet process.

High purity nickel powders can be produced via the carbonyl process. These powders can be used for powder metallurgy applications. ... large iron powder particles.

Process for electrolytic iron powder. US A. Abstract. An improved process for producing electrolytic iron is primarily based on maintaining the electrolytic bath at a low concentration of ferrous sulfate ions in combination with a certain concentration of NH3 and pH in the electrolytic bath.

Powder Production Technologies. ... The sponge iron process. ... selflubricating bearings and still accounts for around 30% of iron powder usage in PM structural parts.

Iron phosphate coating is a great pretreatment for powder coat painting! Learn more about Best Technology''s process for powder coating phosphate wash.

INTRODUCTION Powder metallurgy is a process of making components from metallic powders. Initially, it was used to replace castings for metals which were difficult ...

Jul 11, 2017· How to Make Iron Oxide. ... which is needed to produce magnetite. 6. ... Keep in mind that the process of electrolysis may heat the water.

Iron powder is a basic raw material for the manufacture of powder metallurgy parts which are used in automobiles, appliances, farm and garden equipments, tools, business machines and so on.

2. production of iron and steel powders table of contents introduction short history of iron powder the hÖganÄs sponge iron process

WhatsApp)

WhatsApp)