WhatsApp)

WhatsApp)

Nearly half of this fly ash is reused for purposes such as producing cement Chemically and physically fly ash can have many forms depending upon the type of fuel burned and handling methods

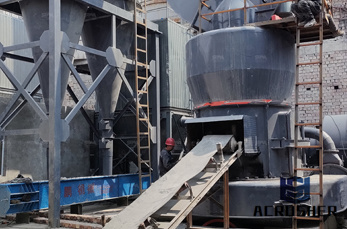

Fly Ash Dryer Being a coveted firm engaged in the process of manufacturing and supplying our clients with a quality range of industrial machines we are also offering them with best quality Fly Ash Dryer This dryer has been widely applauded for its effectiveness and we have incorporated the best quality material in the making of this range

When fly ash is introduced into concrete it reacts with the CaOH 2 to form additional CSH gel In a properly proportioned mix fly ash can improve many of the properties of concrete including Improved workability and consolidation Increased flexural and compressive strengths Improved pumpability Reduced drying shrinkage

The practical implications of the study suggest that dryingscreening of wetstored fly ash to reestablish handling properties and the application of processes to achieve finer fractionsreduce particle size provide options for its recovery and use as an addition in concrete

Fly bricks machine is a special equipment which is used for manufacturing the autoclaved fly ash brick Fly ash making machine is very suitable to produce all kinds of hollow or solid brick with all kinds of raw material clay shale coal slack fly ash etc

The Calsinter process was developed at the US Oak Ridge National Laboratory In this process coal fly ash is blended and sintered with gypsum and limestone at a temperature of about 1000–1200 °C The sinter is then leached with dilute acid Waste solids are removed by filtration and metal values are recovered from the filtrate

During a drying process of 4060 minutes water absorbs heat and turns into vapor which is taken away by exhaust gas Dust collecting system is very important for fly ash dryer In some areas government applies strict environmental protection policy

Dry Bulk Rentals is a supplier of bulk or bagged fly ash lime cement and other products for soil solidification

At these conditions the fly ash concentration in the flue gas was 17 g·Nm 3 −1 which meant over 95 fly ash was trapped in the furnace and discharged as slag 85 of Ni and Cr were bound in the slag as well as 60 of Cu The mass and energy balance analysis indicates that the boiler heat efficiency of an industrial MSW incineration

This Report is devoted to heatcured lowcalcium fly ashbased geopolymer concrete Lowcalcium ASTM Class F fly ash is preferred as a source material than highcalcium ASTM Class C fly ash The presence of calcium in high amounts may interfere with the polymerization process and alter the

Solidification and drying of nontoxic wastes for delivery to approved landfills Charah Solutions is also able to design and install dry ash conversion systems for fly ash to support the development of ash marketing programs and to eliminate wet slurry ash handling systems Charah Solutions has formed Ash Venture LLC

Direct fired rotary dryers account for the lion''s share of bulk solids drying applications and are used throughout a multitude of industries including fertilizer and agriculture mining and minerals specialty chemicals and more They offer heavyduty processing and consistent reliability

The GEOMAX soil stabilization process blends Class C selfcementing fly ash a coal combustion byproduct kiln dust quicklime or cement powder into the soil to bond soil particles Fly ash can be used as a drying agent for saturated soils because it helps reduce the moisture content and allows for compaction – resulting in a more stable base

FEECO has been processing fly ash for over 65 years providing custom highquality agglomeration and material handling equipment for dedusting fly ash and turning it into a more marketable product

Class C fly ash and other high lime fly ash have been found to be very effective drying agents capable of reducing soil moisture content by 30 percent or more The fly ash dries the soil by two basic mechanisms chemical reactions that consume moisture in the soil and by simple dilution

Screw conveyor to transfer cement fly ash and additive to the weighing systems Bucket elevator to transfer sand and fine aggregate to silo Mixing system Dry mortar mixer there are different types of mixers for you to choose from including spiral belt mixer

Coal feeders provide coal to the coal pulverizers mills where the coal is pulverized and dried Dryer coal is easier to pulverize and less mill power is needed to achieve the same coal fineness Additionally with less fuel moisture more complete drying of coal can be achieved in the mill

Sludge drying is a process to dewater and recycle highmoisture sludge as resource there are mainly two ways to dry sludge natural drying and mechanical drying The latter is more efficient The removal of water reduces the sludge quality and volume which is to

SAND AGGREGATE BULK MATERIAL DRYING Tarmac International designs and builds Sand Aggregate and Bulk Material Drying Systems based on our rotary convection dryers Dryer flights can be adjusted to maximize efficiency to accommodate your specific project

The resulting dry fly ash is easier to store and transport and road construction and concrete industries have increased the demand for this material The sale of fly ash for concrete production is potentially an excellent ancillary profit source for your plant

The structural effects of fly ash may be more critical but cosmetic concerns also affect its use in concrete It is more difficult to control the color of concrete containing fly ash than mixtures with Portland cement only Fly ash also may cause visual inconsistencies in the finished surface such as dark streaks from carbon particles

Fly ash serves as a drying agent for soils that are too wet to achieve the required density The drying effect of fly ash in wet soil occurs rapidly allowing you to quickly proceed with construction activities Fly ash also makes soil more resistant to water infiltration Before using fly ash a soil amendment

WhatsApp)

WhatsApp)