WhatsApp)

WhatsApp)

Job Interview Practice Test Why Do You Want This Job? Answer this job interview question to determine if you are prepared for a successful job interview

Advantages of coal based thermal Power Plant. They can respond to rapidly changing loads without difficulty; A portion of the steam generated can be used as a process ...

•Availability of funds 4 CASE STUDY Holtec had carried out a plant operations audit in a dry process cement plant operating at a capacity of about 3,350 tpd clinker.

Module: 5 Lecture: 24 Cement industries Dr. N. K. Patel N P T E L 162 Animation Lime stone or chalk and clay are crushed into gyratory crusher to get 25 cm

Photo of a series of ball mills in a Copper Plant, grinding the ore for flotation.

GRINDING MEDIA FOR THE VARIATIONS IN CEMENT MANUFACTURING. Changing impact conditions can cause conventional grinding media to either work harden or .

Open Type Sand Mills are used in processing enamels, cement primers and emulsions. Apart from this, our sand mills are utilized for processing a wide variety of ...

Hammer Mills – Welcome to Willams Patent Crusher and . Meteor Hammer Mills The Williams Meteor Mill is characterized by high hammertip speed to permit . or ...

The Planetary Ball Mill PM 200 is an excellent choice when a high degree of fineness is required. Grinding down to the nano range. Read more.

Castle cement plant: Ribblesdale, Clitheroe, Lancashire ... Picture: ©English Heritage NMR Aerofilms Collection. Catalogue number A110850.

Monographs : Monograph No 32 December 2014. The Society''s first Monograph for some years has been printed and accompanied the Winter 2014 newsletter.

Figure 2: The integrated cement plants and standalone cement grinding plants in the UAE in 2014, colourcoded by installed integrated cement production capacity in ...

We have more CENTRIFUGAL CONCENTRATORS available also. Call us for more details.

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles.

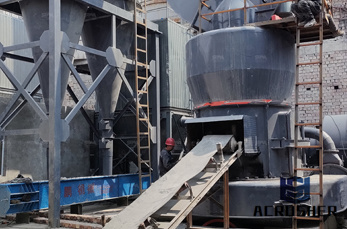

Now cement plant grind the raw mix with the help of heavy wheel type rollers and rotating table. Rotating table rotates continuously under the roller and brought the ...

A cement is a binder, a substance used in construction that sets, hardens and adheres to other materials, binding them together. Cement is seldom used solely, but is ...

OPTIMIZATION OF PLANT OPERATIONS TROUBLE SHOOTING, Dalla Cement Factory (A Unit of Jaiprakash Associates Ltd. .

OPTIMIZATION OF PLANT OPERATIONS TROUBLE SHOOTING, Dalla Cement Factory (A Unit of Jaiprakash Associates Ltd. India)

Used Roller Mills – Brunkan Equipment. Check out our used equipment and rentals! Home; Equipment Rental ; Used Equipment For Sale . ATVs; Ag Feed Equip. .

This small 1 to 2 ton per 24 hour day capacity grinding mill acts primarily as a rod mill but can effortlessly be converted to a ball mill. Thanks to the integrated ...

Cement is a binding agent and is a key ingredient of the most used manmade material: concrete. The demand for cement is strongly correlated to the rate of economic ...

Earle''s cement plant: Hope, Derbyshire ... Picture: ©English Heritage NMR Aerofilms Collection. Catalogue number R20367.

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

We execute the turnkey solutions, turnkey project solutions and turnkey plant solutions for cement manufacturing, fertilizer manufacturing, biomass gasifier ...

WhatsApp)

WhatsApp)