WhatsApp)

WhatsApp)

Chemical Considerations. The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the ...

Cement Kiln Process Specialist, expert trouble shooter for process problems with cement kilns.

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Cement history, in brief, from the Greeks and Romans to the development of Portland cement

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

International journal of advanced scientific and technical research Issue 4 volume 1, JanuaryFebruary 2014 Available online on ...

Machinery and Equipment buys and sells all types of Used Processing Mills for food, pharmaceutical, chemical and mining industries. View our inventory of more than ...

Hammer Mills – Welcome to Willams Patent Crusher and . Meteor Hammer Mills The Williams Meteor Mill is characterized by high hammertip speed to permit . or ...

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

Used Roller Mills – Brunkan Equipment. Check out our used equipment and rentals! Home; Equipment Rental ; Used Equipment For Sale . ATVs; Ag Feed Equip. Blowers; .

Open Type Sand Mills are used in processing enamels, cement primers and emulsions. Apart from this, our sand mills are utilized for processing a wide variety of ...

Traditionally, ball mills are used in cement industry for raw material, fuel and product grinding. Ball mills use an established technology and offer certain advantages.

Industrial Kiln is dedicated to helping you achieve the performance that is required to keep your production lines running at optimized levels.

PENTA Engineering Corporation has been providing design/build services to the cement, lime, mining and industrial minerals industries since 1986.

The heavy duty roller/ball stand combines several outstanding features in one unit. Constructed from a combination of 50mm diameter round and square steel tubes, and ...

The Planetary Ball Mill PM 200 is an excellent choice when a high degree of fineness is required. Grinding down to the nano range. Read more.

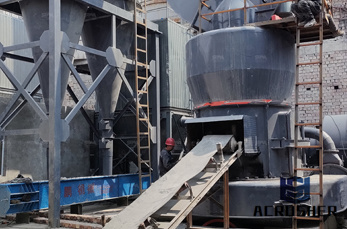

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction ...

Bolted shell liners, tube mill internals, boltless shell liners for cement mills from AIA Engineering Ltd.

A cement is a binder, a substance used in construction that sets, hardens and adheres to other materials, binding them together. Cement is seldom used solely, but is ...

Amy Saunders, Global Cement Magazine The growing cement industry of the UAE Economy Since gaining independence from Britain in 1971, the UAE has had a strong .

Earle''s cement plant: Hope, Derbyshire ... Picture: ©English Heritage NMR Aerofilms Collection. Catalogue number R20367.

•Availability of funds 4 CASE STUDY Holtec had carried out a plant operations audit in a dry process cement plant operating at a capacity of about 3,350 tpd clinker.

Nelson Machinery Equipment Ltd. Liquidations, Consignments, Appraisals since 1992

WhatsApp)

WhatsApp)