WhatsApp)

WhatsApp)

• What is Cement? • History • Overview of the Cement ... • Wet process easiest to ... to proper proportions and ground in the cement mills. •Additives may ...

Additives The raw ingredients of portland cement are ime, si ica, alumina and iron Lime is obtained from ca careous rock deposits and industrial alkali waste ...

Portland Cement Association. 5420 Old Orchard Road; Skokie, Illinois ; ; 1150 Connecticut Avenue, NW, Suite 500; Washington, DC

The table also includes an indication of the primary uses and benefits, along with the cements that they can be used with. The primary effects of the cement ...

Fosroc provides cement additives in liquid or powder form, designed to enhance the strength and workability of cement in construction projects.

The Cement Production Process eHow | How to Videos ... The Cement Production Process. Cement is a dust or fine, powdery substance that makes up concrete, mortar .

List of Common Used Concrete Admixtures (Additives) Share ... are used to delay the chemical reaction that takes place when the concrete starts the setting process.

Rapid Set® Cement. When you''re working on a concrete repair project and time is critical, choose Rapid Set® Cement. Rapid Set Cement is a fastsetting hydraulic ...

Since its establishment in 2006, Al Khalij Cement Company (AKCC) has stood for Health Safety, Quality, Sustainability, Efficiency and Growth.

Technology Overview. Blue Planet''s new biomimetic carbon capture and mineralization technology utilizes several patented scientific breakthoughs.

Glossary < About Cement ... cement additives", these minerals are used in varying proportions during the last phase of the cement production process. The additives ...

Called "cement additives", these minerals are used in varying proportions during the last phase of the cement production process. The additives make it possible to ...

A mobile system and process for manufacturing cement additives and/or concrete admixture products comprise tanks (14, 16, 18, 20, 22) each containing a different raw ...

Edit Article wiki How to Mix Cement. Three Methods: Preparing the Dry Mix Mixing in Water Completing the Process Community QA. Whenever a project calls for a hard ...

cement and the cementing process the reader is referred to the Society of Petroleum ... Cement additives may be divided into two general classifications based on ...

Drying and Primary Grinding. The essential additives quartz, sand and iron ore are added to the homogenised material and this mixture is then ground to a powder with ...

Manufacturing process < All about Cement < Cement : Lafarge Lafarge, building better cities. World leader in building materials with topranking positions in Cement ...

page 3 | Lafarge Cement In the Hardened State > Bond the term "bond" refers to a specific property that can be subdivided into: • extent of bond or degree of ...

How to Use Cement Additives. Cement is a man made mineral based powder which goes through a chemical change or reaction when mixed with water. First it becomes like ...

An electric current is sent by wire to a perferating (perf) gun. The charge shoots small holes through the casing, cement, and a short distance into the shale.

Cementing is the process of mixing a slurry of cement, cement additives and water and pumping it down through casing to critical points in the annulus around the casing or in the open hole below the casing string. The two principal functions of the cementing .

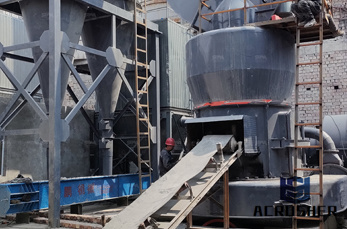

Technical Notebook CEMENT ADDITIVES FOR VERTICAL MILLS Mape. with the implementation of Grinding Aids and to optimise the grinding process in allway into the cement ...

A mobile system and process for manufacturing cement additives and/or concrete admixture products comprise tanks (14, 16, 18, 20, 22) each containing a different raw ...

In experimenting with materials other than what would be considered "traditional", I have found that white portland cement works best for my style and subject ...

WhatsApp)

WhatsApp)